Valmet will deliver a press roll for the TwinRoll wash press at Mercer Rosenthal mill in Germany. The new TwinRoll Press Roll will ensure the availability and performance of the press and increase its lifetime. The replacement roll will be delivered during the second quarter of 2026.

The order is included in Valmet’s orders received of the first quarter 2025. The value of the order will not be disclosed.

“We value Valmet's know-how and experience in the field of wash presses and their willingness to respond to customers' needs. With their help, we can stock a strategic spare part that is unique on the market due to its modified and reinforced design and is intended to guarantee the availability of the wash press for years to come,” says Thomas Herzog, Technical Manager at Mercer Rosenthal.

“We are happy to deliver the replacement roll for the wash press at Mercer’s Rosenthal mill. With Valmet’s proven design – over 4,000 pieces sold in presses and replacements worldwide – and long experience in wash press services, we can support the customer in increasing the availability and lifetime of the roll and the entire wash press area,” says Nils Anspach, Product Sales Manager at Valmet.

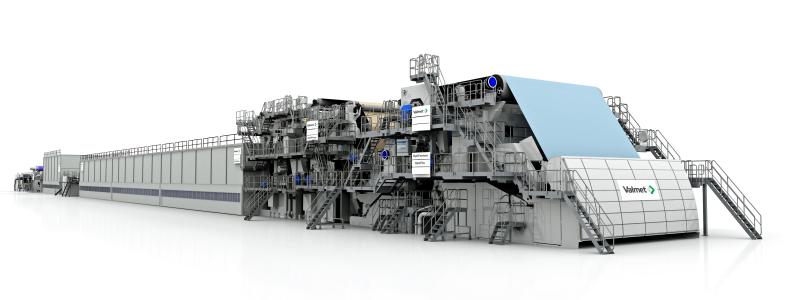

The TwinRoll Press Roll design represents Valmet’s roll expertise gathered over several decades. Valmet Perforated Plate HF on roll surface enables high drainage capability and a long lifetime. Plates are assembled on one-piece mantle, providing maximal support for high press loads. The roll has exchangeable edge rings and a three-chamber lining system for reliability and serviceability.

Mercer International is one of the world's largest producers of market pulp and a growing leader in the solid wood products space. The company has facilities in North America, Europe, and Australia. The Mercer Rosenthal mill produces about 360,000 tonnes of elemental and total chlorine-free Northern Bleached Softwood Kraft (NBSK) pulp per year and 400,000 MWh of renewable electricity.