On Recycling Day, Maflex, a leader in the tissue converting sector in Italy, explores the benefits and challenges associated with using recycled paper in converting lines. The topic of recycling and all related environmental sustainability practices is important not only for the paper industry but also globally, where the urgency for effective and responsible choices is increasingly evident.

Benefits and challenges of using recycled paper

Using parent reels of recycled paper offers significant benefits for converters, such as promoting environmental sustainability and potentially reducing raw material costs. "However, it is essential to also consider the additional processing costs, and for example, the regulatory requirements that, in some countries, may limit the use of certain types of recycled paper. Moreover, in markets less oriented towards eco-sustainability, consumer perception can negatively affect the reception of recycled paper, viewing it as inferior quality," explains Luca Mazzotti, General Manager of Maflex.

Importance of collaboration with manufacturers

Maflex actively promotes recycling in all its forms and supports the use of recycled paper in the converting industry. The company is particularly favorable to eco-friendly solutions in the sector, from technological innovations on machinery aimed at reducing environmental impact to sustainable practices integrated into finished products. "For every new tissue converting project, the starting point is the roll that the customer wants to create and offer to the final consumers." In this process, those who choose to use recycled raw materials instead of virgin fiber find in Maflex a reliable and proactive partner. "Our company is committed to working closely with customers to explore the most sustainable and technically advanced options, ensuring that each project not only meets but exceeds any expectations and is a success."

The technical challenges of using recycled paper in the tissue converting process

Using recycled paper reels in the tissue converting process presents a series of technical challenges that require careful evaluation to ensure production efficiency and the quality of the final product. "On the occasion of Recycling Day, we thought to share our reflections, the result of experience and expertise gained in numerous similar cases." By working closely with an experienced manufacturer like Maflex, converters can address and overcome these challenges, optimizing both sustainability and profitability of the process. "Only a deep partnership can effectively address these critical issues and identify the right solution whenever needed."

The 3+1 Technical factors to consider

"Effectively working with recycled paper means more frequent and careful adjustments. It means closely monitoring the production process and the behavior of the paper, as well as using specific systems and components." In addition to economic and market challenges, there are indeed several important technical factors to consider. "We have identified four main technical factors that, in our view, significantly impact the production process and machinery. Knowing and considering them during the planning phase can be an advantage."

The first technical factor to consider is definitely the quality of the fiber itself, followed by the risks associated with contamination and impurities during its processing, as well as the variability of the raw material. Last but not least is the production speed. Let's look at them in detail.

- Fiber Quality.

- Contamination and Impurities.

- Variability of Raw Materials.

- Production Speed.

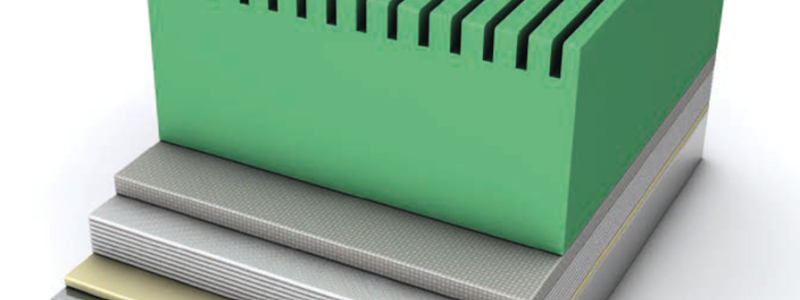

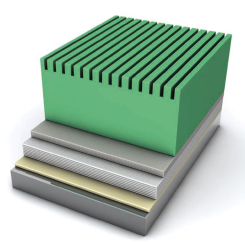

Recycled paper may have shorter and weaker fibers compared to virgin paper. This affects the strength and softness of the final product and, of course, the entire production process. "Technologically, precise control of the tension of each ply is crucial at every stage to ensure consistent and efficient production. When producing embossed rolls, choosing the right engraving is also essential."

Parent reels of recycled paper can often contain inks, adhesives, and other non-fibrous materials that cause complications during the production cycle: clogs, stops, and damage to converting machines. "With the use of recycled raw materials, the risk of contamination of the machinery also increases. Maflex implements advanced systems for control, filtration, and cleaning, ensuring uninterrupted production and that each roll produced meets the highest quality standards."

The quality of recycled paper can vary significantly depending on the source and collection process; different supplies can have strongly variable characteristics. Transforming parent reels of this type can greatly affect the performance of the production of toilet rolls or kitchen towels and the characteristics of the finished product. "The difficulty increases when producing embossed or glued rolls with recycled paper, due to its inherent tendency to react differently during the process. The risk of contaminating the rollers with glue is very high, which inevitably leads to breaks in the ply and consequent production stoppage."

Speed is a critical aspect when looking to transform parent reels of recycled paper. Working with this raw material may require limitations in productive performance. "Operating at a constant speed aims to maximize the efficiency of tissue converting plants by minimizing downtime, especially with the use of parent reels with critical characteristics."

Effective transformation of recycled paper reels requires precise adjustments, rigorous monitoring, and the selection of appropriate technical solutions. Maflex is committed to providing equipment which specifically meets each client's needs, maximizing efficiency and ensuring superior performance in every production context.

Maflex operates since 1997 in the tissue converting machineries industry. The experience gained over the years has led us towards specializing in the manufacturing of complete tissue converting lines. The philosophy pursued by the management of Maflex is to build modern machinery in the symbol of reliability. Particular importance is given to safety, ease of use and to personalization according to the customer’s requests.