ABB has built on its relationship with Södra Cell, Sweden’s largest forest-owner association and leading pulp manufacturer, and will deploy advanced process control (APC) at the Mörrum mill. The new order comes under a strategic partnership between the two companies as they fulfil an ambition to develop new levels of efficiency, engagement and digitalization across the producer’s operations.

The project follows successes where solutions from ABB were implemented for bleach and digesters at Södra Cell’s pulp mill in Mönsterås and for bleach at the mill in Värö. At Mörrum, ABB will provide extended functionality for the existing ABB Ability™ System 800xA® distributed control system (DCS) through APC for the bleaching process on one of two production lines. The objective is to repeat improvements in process stability and reduced resource consumption achieved in the other facilities.

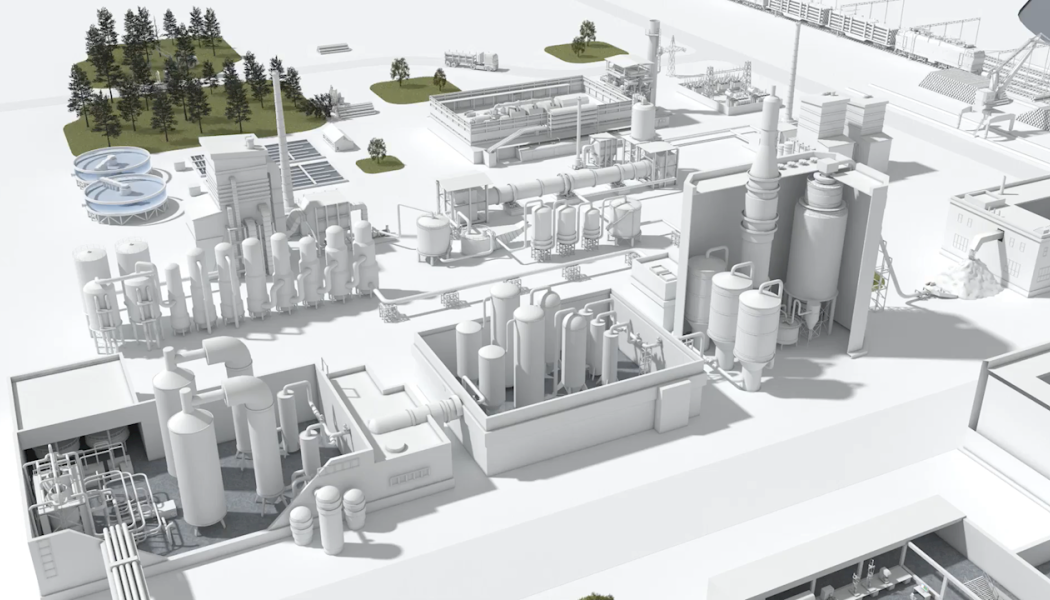

Södra Cell owns some of the world’s most modern and high-tech pulp mills, and has set ambitious targets for efficiency and sustainability, including emissions reduction goals in line with the 2015 Paris Agreement.

“We look forward once again to be working with ABB to implement another APC at a Södra Cell mill,” said Marie Boman, Project Manager, Södra Cell. “We see a strength in being able to take advantage of previous experiences from our other mills’ APC projects, together with deep process and control system knowledge of the Mörrum mill and having ABB control experts of APC application and projects in the team. One successful previous experience was the tight collaboration between the project team and the process operators for the process area, and now I look forward to leading the project for this APC implementation at the Mörrum mill.”

ABB will work in close collaboration with Södra Cell’s mill experts to implement the solution. This will include operational and process analysis, development and verification of models, implementation in the control system as well as training and handover to the operating organization. The delivery is planned to be commissioned before the end of 2025.

“We are proud of the great collaboration and operational results we have been able to deliver to improve Södra Cell’s competitiveness by optimizing quality and consistency in the production,” said Martin Björnmalm, Local Business Line Manager Pulp & Paper, ABB Process Industries. “Gaining the trust and opportunity to bring the solution to a third mill is a great example of our commitment to help our customers outrun the competition.”

Integrating APC into the existing operator environment, with ABB Ability™ System 800xA® at its core, will enable fully automated operations and reliable outcome predictions. Södra Cell will be able to optimize and prioritize crucial operational processes in the bleach plant based on data-driven decisions. APC is one of several examples of ABB systems being expanded with new functionalities to improve customers' profitability, efficiency and working environment.

Expected results for the mill in Mörrum are a more stable optimized bleaching process with reduced variation of brightness and reduced chemical consumption as well as improved bleaching processes.

Södra Cell’s Mörrum mill specializes in both premium paper pulp and dissolving pulp for textiles and other applications, including the unique OnceMore® process. With an annual production capacity of 300,000 tonnes of softwood paper pulp and 170,000 tonnes of hardwood dissolving pulp, the mill is a key player in sustainable pulp production. Mörrum has a strong track record of investment in energy efficiency, green energy, and environmental best practices, supported by a team of 350 skilled employees.

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and more than 110,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps process, hybrid and maritime industries outrun – leaner and cleaner. go.abb/processautomation

The views expressed in this media release are solely