The Adami Group has commissioned full-line supplier Voith to build a complete OCC BlueLine stock preparation plant with 4.0 technology for its factory in Santa Catarina, Brazil. The project includes a comprehensive Process Line Package (PLP), the supply and installation of all main components and detailed engineering. Commissioning is scheduled for October 2025.

“This project not only strengthens the long-standing partnership between Adami and Voith but also demonstrates the shared commitment of both companies to innovation, quality and operational excellence”, says Rodrigo Ruffo, Application and Sales Manager at Voith Paper.

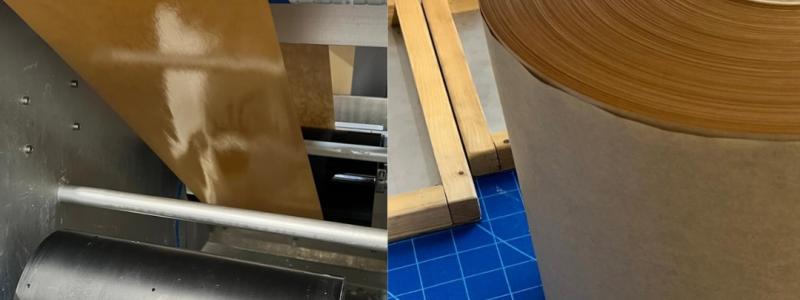

With key components such as the new InduraClean heavy-duty cleaning system, the line is specially designed to handle high levels of contamination, a necessary requirement for Adami due to the nature of the raw material. The flexibility of Voith's OCC systems in dealing with varying degrees of contamination was a decisive factor in Adami's choice of Voith.

In addition to the OCC system, the order also includes 4.0 technology solutions for the autonomous operation of the stock preparation system. With the products OnView.MassBalance, OnControl.SmartProtect and the OnView.RejectCamera, the Santa Catarina mill is the first in Latin America to use these cutting-edge technologies. This move reflects Adami's commitment to remain at the forefront of the industry and to develop innovative processes and technology.

The Adami Group, based in Caçador in the state of Santa Catarina, Brazil, was founded in 1942 and operates in the timber sector (splitting and selling raw wood). The family-owned company currently has 2,000 employees and is made up of the Forestry, Timber, Paper, Packaging and Electricity business units.

The main products developed for the timber industry are sawn and processed timber, pallets and pellets, panels, frames and doors. In its core business, it produces paper for packaging, corrugated sheets and boxes, supplying various sectors of the economy, particularly the food sector (animal protein).