ProJet received an order for Power Cleaners (dryer fabric cleaners) from Subam Paper, India. The value of the order will not be disclosed. The order was received in September 2024 and will delivered in 2025.

Of course, all Power Cleaners will be ProJet’s Power Cleaner 2.0, the upgraded version. The upgrade consists of a smaller cleaner head, more nozzles at higher pressure and improved vacuum/discharge system. The combination of all these improvements is an increased cleaning efficiency, exactly what Subam Papers needed for its Dryer Fabrics.

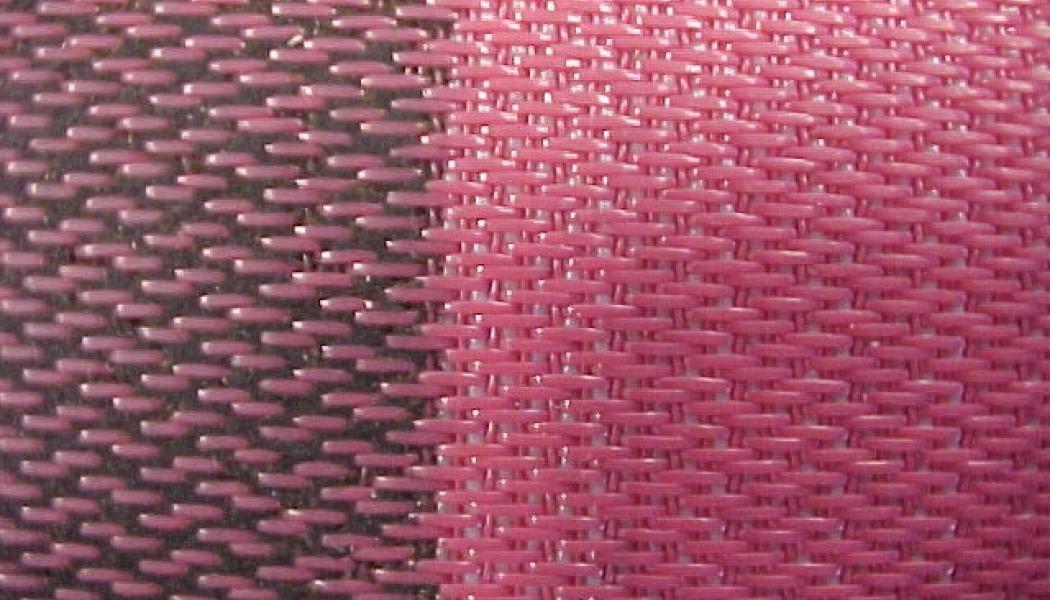

The Power Cleaner cleans the Dryer Fabrics continuously, 24 hours a day, as long as the machine is running. Older technologies are operated in batch cleaning mode, allowing the dryer fabrics to get dirty first, losing permeability, and then trying to restore that permeability again. This leads to uneven permeability profiles over time, mostly leading to paper quality issues and more broke. The above graph shows the advantage of continuous cleaning, leading to a more stable moisture profile, less broke and longer lifetime of fabrics. Dryer fabric contamination is on the rise due to the increasing use of secondary fibres, recycling of coated broke, increasing use of sheet fillers, an increased use of recycled mill water supplies, and the increased use of process chemicals.