Valmet will supply a new tissue production line with the latest technology to Metsä Tissue’s mill in Mariestad, Sweden. The delivery also includes an extensive package of stock preparation, automation and service solutions. The order is part of Metsä Tissue’s development program ”Future Mill”, aiming for world class environmental and technological performance in tissue production.

The order is included in Valmet’s orders received of the first quarter 2023. The value of the order will not be disclosed.

Valmet and Metsä Tissue have a long history of cooperation. Recently the PM 10 machine at the customer’s Mänttä mill in Finland was successfully rebuilt. In the past few years Valmet has also supplied a series of energy saving and efficiency upgrades to Metsä Tissue’s other mills, including Advantage ReDry energy saving solutions, Advantage ViscoNip presses, refiners and automation controls.

The new Valmet tissue machine is equipped with the latest technology to reduce energy and water consumption and CO2 emissions.

“With the new tissue machine, we will increase the offering of locally produced sustainable virgin fiber-based tissue paper to the Scandinavian market. It enables reliable local deliveries of high-quality tissue to the consumers. The new technology brings big environmental benefits. In addition to the energy savings, we can reduce the process water in the paper making process by 50 percent,” says Esa Paavolainen, Vice President projects, Metsä Tissue.

”It’s a pleasure to get the opportunity to contribute to the establishment of a completely new tissue mill in Sweden. We are honored to be trusted in delivering a tissue line with the latest technology to Metsä Tissue in Mariestad. Our long history of collaboration is an excellent foundation for a successful project execution,” says Jari Vähäpesola, President, Paper business line, Valmet.

The new tissue machine will have a design speed of 2,200 m/min and is optimized for low energy consumption and enhanced quality of the final product.

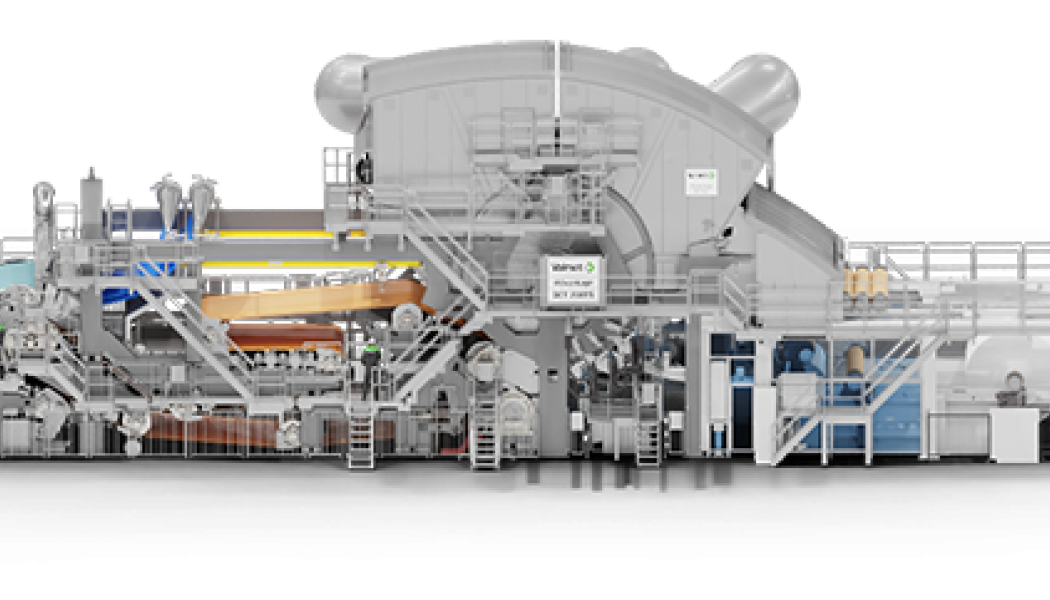

Valmet’s scope of delivery will comprise a complete tissue production line featuring full stock preparation with bale handling and a Valmet Advantage DCT 200 TS tissue machine with latest technology for high efficiency, low energy and water consumption and reduced CO2 emissions.

Furthermore, the delivery will include Valmet quality control and monitoring system, complete engineering, installation supervision, training, start-up, and commissioning. Valmet will also supply start-up clothing as well as master maintenance data services and remote support from Valmet’s Performance Center.

The new line will add 70,000 tons of tissue made from virgin fiber to the mill’s current production. The mill’s total annual capacity will increase to 145,000 tons.