Svante Technologies Inc., a leading next-generation carbon capture and removal technology company, announced that it is developing a world-first carbon capture and storage project at its Ashdown Pulp Mill in Arkansas.

The project is a major step forward for Svante in deploying its next generation carbon capture and disposal technology to the pulp and paper industry, demonstrating its ability to generate high-quality carbon removal (CDR) credits and improving the industry’s operational sustainability. The project has been selected by the U.S. Department of Energy’s (DOE) Industrial Efficiency and Decarbonization Office (IEDO) to negotiate a cost-share agreement in the amount of up to $1,499,889 (pending award number: DE-FE0032652). The DOE grant will fund a Pre-FEED (preliminary front-end engineering design) study by Svante and its project partners Paper Excellence and Wood to evaluate the success of a post-combustion carbon capture technology using the Ashdown pulp mill's recovery boiler flue gas.

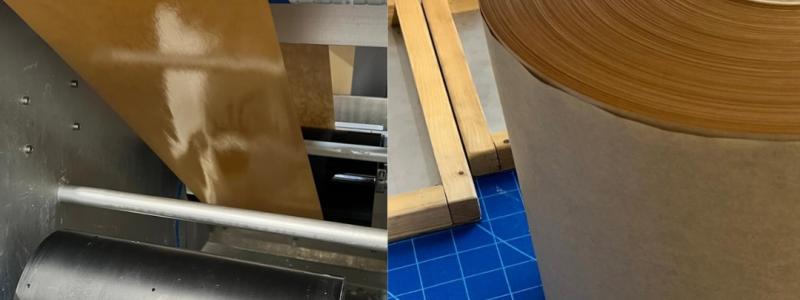

Svante's revolutionary rotating solid adsorption system uses advanced metal organic framework (MOF) based filter technology, which has the following outstanding advantages:

- Significantly reduce the cost of capturing carbon dioxide: Svante's unique technology can apply low-burn waste heat to the carbon capture process, significantly reducing its energy consumption and the total cost of carbon capture.

- Modular, Simple Carbon Capture Plant Design: Svante's modular carbon capture plant design reduces capital costs, minimizes the impact on existing plant operations, and can be seamlessly integrated with pulp mills.

- Environmental Responsibility: Svante’s solid adsorbent nanomaterials are inherently benign, avoiding harmful secondary emissions and liquid waste/wastewater, ensuring a clean and safe carbon capture method. In addition, Svante's filter material design is also based on sustainable production and recyclability.

Once the project reaches the Final Investment Decision (FID) stage, it will have a transformational impact on the pulp and paper industry by achieving the following:

- Remove up to 1.5 million tonnes of organic CO2 , as the project uses sustainable biomass to remove CO2 from the atmosphere, rather than “anthropogenic” or man-made CO2.

- Unlocking new revenue streams through carbon dioxide removal (CDR) credits in the voluntary credit market is a compelling business case for the pulp and paper industry.

- Demonstrate the unique advantages of Svante carbon capture technology applied to the pulp and paper industry.

“The pulp and paper industry offers a unique opportunity to combine technology and nature to remove carbon dioxide from the atmosphere,” said Claude Letourneau, President and CEO of Svante. “Svante’s metal-organic framework-based carbon capture technology has the potential to revolutionize the way industrial facilities manage emissions, and we believe this program can pave the way for further application in a variety of industries.”

Earlier this month, Tenaska and Svante announced the signing of a memorandum of understanding to collaborate on an end-to-end carbon capture and storage project . Tenaska has multiple Category 6 permit applications under review and is committed to providing sustainable and economical carbon capture and storage (CCS) pathways across the United States, including the Sugarberry CCS Hub in Texas.