Procemex, a member of the Andritz Group,has received an order from Billerud to supply a OnePlatform web monitoring and web inspection system with winder and re-winder controls for the board mill in Gävle, Sweden.

This new system will replace the existing ones, enhancing reliability and performance. With this investment, Billerud will strengthen its capability to meet the highest quality needs of its liquid board packaging customers and increase its production efficiency. System installation is scheduled for the third quarter of 2025.

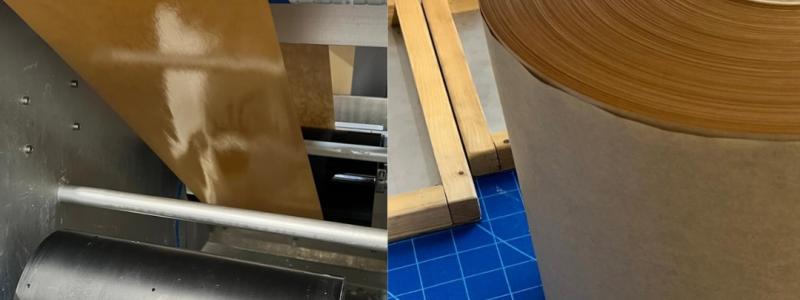

Procemex’s scope of web inspection includes multiple measurement geometries and technologies to efficiently detect various types of defects. High-resolution low-angle reflection and 3D defect detection will ensure effective identification of elevated defects and indents. The innovative Procemex UV light detection technology will detect even the most subtle oil defects, ensuring superior product safety for BM5’s liquid packaging board. The scope also includes high-resolution high-angle reflection and transmission detection for comprehensive product quality assurance.

Throughout the system, a total of 120 smart cameras will be provided. The fully integrated web monitoring system features 40 extremely light-sensitive Procemex Lumina Supersense smart cameras paired with powerful Procemex Eco strobe lights. Every web monitoring camera position is equipped with the latest Procemex ProClean pinhole technology, guaranteeing continuous sheet visibility while reducing maintenance needs.

The scope of supply will also include winder and re-winder control (ATC), enabling efficient and optimized winder operation.

Additionally, Procemex will provide system installation supervision, commissioning, training, and start-up support.