The new converting line, developed by Maflex, provides an advanced and flexible solution to produce high-quality toilet paper and paper towels for domestic use. Although primarily known for its industrial lines, with the HERMES line, the Italian company based in Lucca, in the heart of the "Tissue Valley," is making a significant impact in this market segment as well.

"It was an opportunity to bring our experience and innovation to this segment. When converters aim for superior quality products—soft and voluminous, designed to satisfy the most demanding consumers—technology must adhere to certain standards. With the HERMES line, we have offered the best solutions, including the integration of the Constant Winding System, our response to the high-volume demands of the tissue market," explains Renato Del Monte Technical Salers Manager.

Technical Features of the HERMES Line: Proven Strengths and Innovations

The HERMES Line has been designed to provide customers with consistent production, aligning with the company's long-standing commitment to efficiency in performance. It aims to minimize downtime while ensuring the quality of the produced rolls. "We believe that reliability means consistency and that simply increasing speed doesn't always lead to greater productivity. Our focus is on optimizing the actual running time of a production shift. Customers appreciate the constant speed, which allows for more efficient production of higher-quality products," explains Luca Mazzotti, General Manager.

With a speed of 600 m/min, the HERMES line produces high-quality toilet paper and paper towels, including medical towels, with options for embossed/laminated/smooth finishes and diameters ranging from 90mm to 200mm.

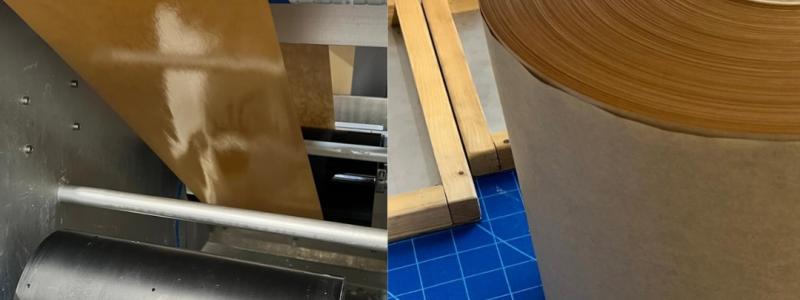

A series of automated systems for rapid product changeovers provide the necessary flexibility and optimal efficiency. All parameters, such as core size, number and length of perforations, roll diameter, etc., can be set via the control panel. The line features two UF 180 front-loading unwinders, capable of handling rolls with a width of 2750 mm and diameters up to 1800 mm. These unwinders are equipped with a splice detection system and automatic web alignment system.

The double embossing laminator model HERACLE features ZERO-FLEX rubber rollers (optional), ensuring consistent patterning across the entire sheet regardless of applied pressure. These rollers also enable the conversion of both soft and very dense products, significantly enhancing production flexibility. The HERMES rewinder, equipped with a mobile lower roller, ensures more uniform and voluminous winding. "This integration allows for the production of soft and consistent rolls—a solution that the consumer market demands," says Eng. Del Monte. The Constant Winding System, which ensures even winding from the first wrap, reflects Maflex’s commitment to listening to and meeting customer needs. «Meeting Your Needs at Every Turn» is a guiding principle represented in the technology. It offers several advantages to producers, including optimizing roll volume: either the same length of paper with a larger diameter or less paper with the same diameter (lower weight), allowing for more efficient resource management. It ensures consistent winding uniformity from start to finish, enhancing the final product's quality.

The goal is to create a Premium product that meets the expectations of high-end consumers who demand greater softness and comfort. The converting line is completed by the IVI Tail Sealer, which features a mobile blade glue distribution system for even edge sealing; the LA 200M accumulator, equipped with an automatic loading system and a carousel discharge for quick loading of the HESPERIA 4c four-channel log saw with automatic clamps.

HESPERIA 4c log saw which offers maximum precision and speed in roll cutting, enhancing the overall efficiency and flexibility of the line.

Flexibility and Efficiency: the Modular Philosophy of Maflex

This HERMES line embodies one of Maflex’s key principles: adherence to a modular approach. This design model offers numerous advantages, including fast, seamless installation with minimal downtime and lower installation costs, as well as ease of implementation and updates without complex interventions, allowing for greater flexibility and adaptability. "We often highlight the residual value to our customers.

Each unit retains high residual value, providing an additional economic advantage and facilitating potential resale or upgrades," explains Eng. Mazzotti. Maflex does not offer off-the-shelf solutions but focuses on customized and diverse options. Each line is designed according to the client's specific needs, aiming for perfect integration with existing processes and maximizing production efficiency. The HERMES Line strengthens Maflex’s position in the consumer segment. "Attention to customer needs and commitment to tailored solutions lead to high results and long-term relationships: both parties aim for significant ambitions," emphasizes Mazzotti. "We have proven to be a reliable partner capable of innovating and providing technologies suited for the growth of our partners who want to make a difference in the tissue sector and excel in volatile and complex markets," concludes Luca Mazzotti.