“Meeting Your Needs at Every Turn represents us impeccably. Over the years there have been several occasions and as many requests that justify this statement," explains Eng. Luca Mazzotti, GM of Maflex. The 3Ps of Maflex are Personalization, Preparedness, and Partnership.

"We tend to diversify and propose projects tailored to the converters ambitions, production characteristics, and the dynamics of the markets in which they operate, rather than canned packages. There are many producers with many different needs in this industry.”

"Meeting Your Needs at Every Turn" expresses the ability to respond promptly to meet specific needs, the commitment to providing solutions that are as innovative, reliable, and diverse as the everyday needs they serve.

Tissue converting is very fluid: worldwide, demands are affected by general trends and motivation. This can be due to the specific territory, industry constraints, or original production needs. Maflex stands as a ideal partner. "Every tissue product requires the right equipment to face the race! The goal is to achieve concrete results in the marketplace: OEMs teaming up with converters." The machinery is extremely flexible and the proposed lines are based on the modular philosophy: you can have equipment with unique features. The Engineering Dept does not exclude the integration of customized solutions.

“The required do not always demand revolutionary technologies, but they often pay off in advantages in production efficiencies.” For a high-performance continuous converting line, capable of processing large-diameter parent reels and producing a wide range of industrial rolls, a competitive layout was designed that provides maximum efficiency in terms of production flexibility and ensure fast changeovers with minimal downtime.

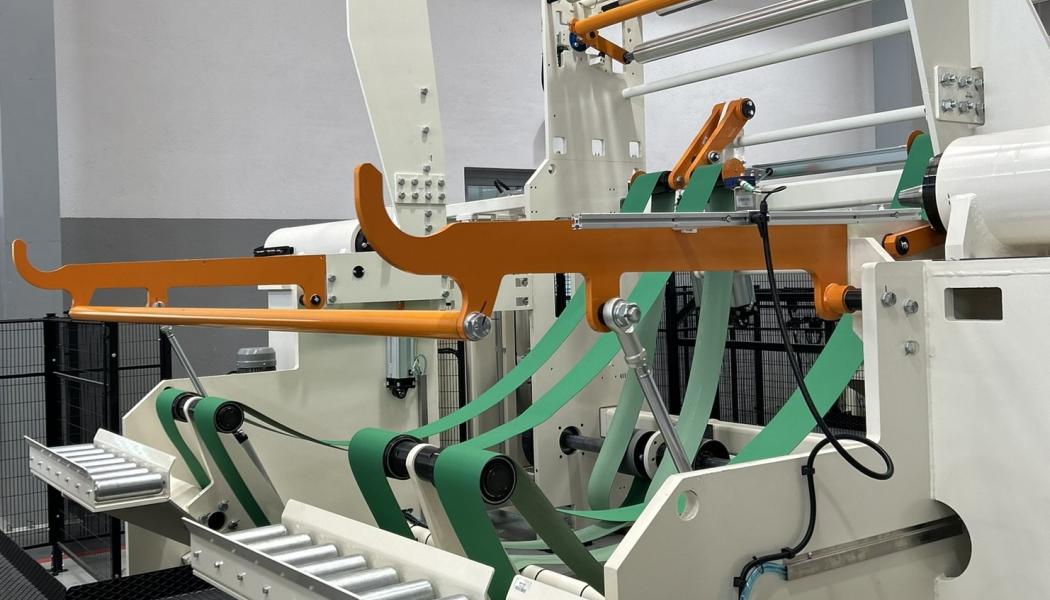

The customer was looking for a professional product line capable of operating at a constant speed of 600 m/min and ensuring maximum performance. "Our project included top-loading unwinders model UT 250 that easily process tissue paper reels up to 2500 mm in diameter at the required speed. The low ceiling of the building for which the line was intended, however, would not have allowed proper use of the unwinder with reels larger than 2100 mm in diameter."

Giving up the features of the UT 250 to use only smaller reels would have meant a significant decrease in overall productivity. The project would have lost its main objective: to meet the customer's ambition with a high-performance line. “We came up with an ad hoc modification to facilitate the loading and unloading of the large parent reels by avoiding top loading.” The extraction of finished reels and the insertion of new ones takes place from a reduced height, in a much faster time and makes the operations related to loading the reel with the overhead crane, which are often subject to special procedures, easier, faster and safer. “This system has been proposed before, its value realized because of the solid benefits it offers.” Close collaboration is the added value of the innovation journey. This provides insight into what is needed and into original production ideas for which timely and user-friendly changes are needed. Feedback is of fundamental value in continuous improvement and research and development.

"Another case came up with the need to produce on both standard paper width (reel width 2750 mm) and reduced width (reel width 900/1000 mm). This solution would have limited the production potential of the line by going against the principles of optimization and performance, so the goal was to prevent the customer from losing productivity."

Being faster does not always mean being more productive as well. Working consistently allows you to produce more efficiently and with higher quality. This is why the company focuses on maximizing machine efficiency while minimizing downtime, such as production changes. "So we had to make sense of the customer's specific need, avoiding wasted time and enhancing line performance instead of inhibiting it. To please him without betraying our principles!" A double unwind system was proposed, which maximized time and performance and led the plant to next level of efficiency and productivity, met the needs perfectly.

Maflex stands out for its willingness to fulfill specific needs. Working closely with the manufacturer, from design to production, is aimed at ensuring full satisfaction. From this synergy comes original and beneficial ideas.

"These are just a few examples that perfectly reflect our approach from Lucca to Green Bay. Recently, in fact, the Maflex America team worked closely with a multi-national tissue manufacturer and provided a novel, “out-of-the-box” solution to a complex, product-specific need. The path to innovation is an ongoing journey of incremental progress that, together, create significant and lasting impact.